Festo Pneumatic Components on Powermatic Associates

Pneumatic Components- Festo

Components that are pneumatic are crucial elements of a pneumatic system, using compressed air to manage movements and carry out a range of tasks in industries like manufacturing, construction, and automation.

Pneumatic Components

General Guide & Overview

Pneumatic components are essential parts of a pneumatic system that utilizes compressed air to control movements and perform various tasks in industries such as manufacturing, construction, and automation. These components are designed to optimize automation and control and are favored by many industries for their cost-effectiveness and reliability.

Industrial pneumatic systems typically consist of a compressor, receiver, valves, and actuators. The compressor converts the air into compressed air, which is then stored in a receiver. Valves control the direction and flow of the air, while actuators are responsible for the required movement of the system.

Additionally, air preparation components such as filters, regulators, and lubricators play a crucial role in maintaining the performance and longevity of the pneumatic system.

Understanding the functions and applications of pneumatic components is key to harnessing the power of pneumatic systems effectively. In this guide, we will explore the various components of a pneumatic system and their functions, providing you with a comprehensive overview.

Advantages and Limitations of Pneumatic Systems

Pneumatic systems offer several advantages that make them popular in various industries. These include simplicity of design and control, reliability, and safety.

One of the key advantages of pneumatic systems is their simplicity. They can be easily designed and operated using standard components, making them cost-effective and efficient. This makes them a popular choice for industries that require automated processes.

Pneumatic systems are also known for their reliability. They can continue to function even if there is a loss of electrical power, ensuring uninterrupted operation. This is especially important in critical applications, where downtime can be costly and disruptive.

Additionally, pneumatic systems are considered safe to use. They are less prone to shock damage compared to hydraulic systems, reducing the risk of accidents. They also have a low risk of fire, making them suitable for applications where fire hazards are a concern.

However, it's significant to note that pneumatic systems also have limitations that need to be taken into account. One limitation is that they are prone to leakage. Air can escape from the system, leading to a decrease in performance and efficiency. Regular maintenance checks are necessary to detect and address any leakage issues in order to prevent potential problems.

Pneumatic systems also require maintenance and repairs to ensure their optimal functioning. Before any repairs, the system needs to be depressurized correctly to avoid accidents. Temperature and vibration changes can affect the performance of pneumatic systems, so it's important to consider these factors and take appropriate measures.

Components and Design of a Pneumatic System

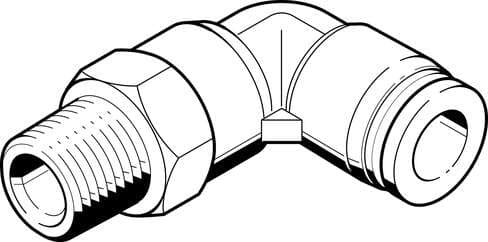

A pneumatic system is composed of several essential components that work together to optimize its performance. The key components of a pneumatic system include an air compressor that converts the air into compressed air, an air tank that stores the compressed air, and an air filter that removes contaminants from the air before it enters the system.

To ensure stable and controlled operation, a regulator is used to adjust and maintain the desired pressure of the air within the system. Additionally, a lubricator is employed to provide lubrication, reducing friction and wear on the components, thus prolonging their lifespan.

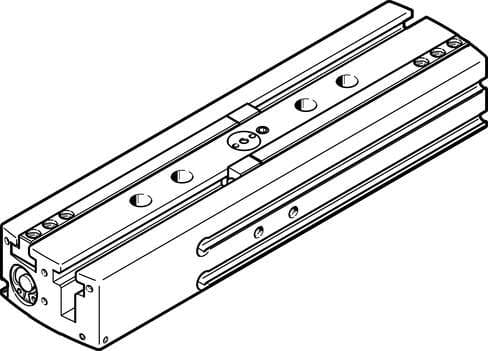

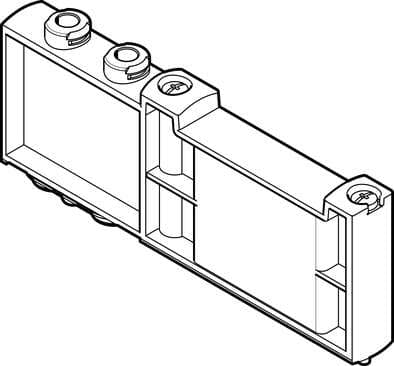

The control valve is responsible for controlling the flow of air within the system, allowing for precision and flexibility in the movement of the actuators. These actuators, which can be in the form of cylinders or motors, convert the compressed air into mechanical movement, enabling the system to perform the desired tasks.

In designing a pneumatic system, careful consideration must be given to the arrangement and placement of these components. Proper positioning ensures an efficient and logical flow of air, reducing energy loss and optimizing performance. By strategically positioning the components, operators can achieve smooth operation and enhance the system's overall effectiveness.

FAQ

Pneumatic components are essential parts of a pneumatic system that utilize compressed air to control movements and perform various tasks in industries such as manufacturing, construction, and automation.

The main components of a pneumatic system include an air compressor, an air tank, an air filter, a regulator, a lubricator, control valves, and actuators.

Pneumatic systems offer advantages such as simplicity of design and control, reliability, and safety. They are easy to design and operate, even without electrical power, and are less prone to shock damage and fire.

Pneumatic systems can be prone to leakage and require regular maintenance checks. The system needs to be depressurized correctly before repairs, and temperature and vibration changes can affect its performance.